Maintenance-type radial spherical plain bearings are designed to provide reliable performance and require periodic maintenance to ensure optimal operation. These bearings require regular lubrication to maintain proper functioning and prevent excessive wear. They are commonly used in applications where maintenance intervals can be scheduled and where lubrication can be easily accessed. Maintenance-type radial spherical plain bearings offer excellent load-carrying capacity, self-alignment, and durability, making them suitable for a wide range of industrial and automotive applications that can accommodate regular maintenance.

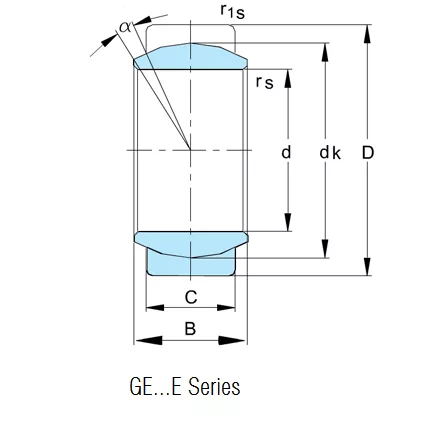

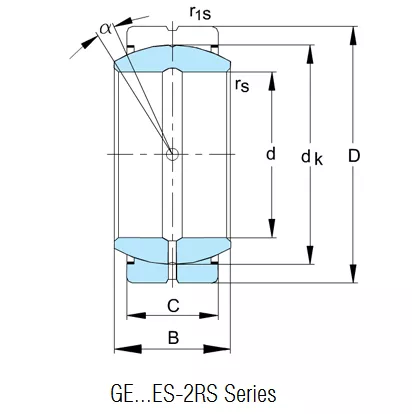

| Part No. | Dimensions /mm | Load ratings KN | Weight kg | ||||||||

| d | D | B | C | dk | R1s | R2s | α | dyn. | stat. | ||

| min | min | ≈ | C | C0 | |||||||

| GE5E | 5 | 14 | 6 | 4 | 10 | 0.3 | 0.3 | 13 | 3.4 | 17 | 0.005 |

| GE6E | 6 | 14 | 6 | 4 | 10 | 0.3 | 0.3 | 13 | 3.4 | 17 | 0.004 |

| GE8E | 8 | 16 | 8 | 5 | 13 | 0.3 | 0.3 | 15 | 5.5 | 27.5 | 0.007 |

| GE10E | 10 | 19 | 9 | 6 | 16 | 0.3 | 0.3 | 12 | 8.15 | 40.5 | 0.011 |

| GE12E | 12 | 22 | 10 | 7 | 18 | 0.3 | 0.3 | 11 | 10.8 | 54 | 0.016 |

| GE15ES GE15ES2RS | 15 | 26 | 12 | 9 | 22 | 0.3 | 0.3 | 8 | 17 | 85 | 0.025 |

| GE16ES GE16ES2RS | 16 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 10 | 21.2 | 106 | 0.041 |

| GE17ES GE17ES2RS | 17 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 10 | 21.2 | 106 | 0.041 |

| GE20ES GE20ES2RS | 20 | 35 | 16 | 12 | 29 | 0.6 | 0.3 | 9 | 30 | 146 | 0.061 |

| GE25ES GE25ES2RS | 25 | 42 | 20 | 16 | 35.5 | 0.6 | 0.6 | 7 | 48 | 240 | 0.11 |

| GE30ES GE30ES2RS | 30 | 47 | 22 | 18 | 40.7 | 0.6 | 0.6 | 6 | 62 | 310 | 0.14 |

| GE35ES GE35ES2RS | 35 | 55 | 25 | 20 | 47 | 0.6 | 1 | 6 | 80 | 400 | 0.22 |

| GE40ES GE40ES2RS | 40 | 62 | 28 | 22 | 53 | 0.6 | 1 | 7 | 100 | 500 | 0.3 |

| GE45ES GE45ES2RS | 45 | 68 | 32 | 25 | 60 | 0.6 | 1 | 7 | 127 | 640 | 0.41 |

| GE50ES GE50ES2RS | 50 | 75 | 35 | 28 | 66 | 0.6 | 1 | 6 | 156 | 780 | 0.53 |

| GE55ES GE55ES2RS | 55 | 85 | 40 | 32 | 74 | 0.6 | 1 | 7 | 200 | 1000 | 0.94 |

| GE60ES GE60ES2RS | 60 | 90 | 44 | 36 | 80 | 1 | 1 | 6 | 245 | 1220 | 1 |

| GE70ES GE70ES2RS | 70 | 105 | 49 | 40 | 92 | 1 | 1 | 6 | 315 | 1560 | 1.5 |

| GE80ES GE80ES2RS | 80 | 120 | 55 | 45 | 105 | 1 | 1 | 6 | 400 | 2000 | 2.2 |

| GE90ES GE90ES2RS | 90 | 130 | 60 | 50 | 115 | 1 | 1 | 5 | 490 | 2450 | 2.7 |

| GE100ES GE100ES2RS | 100 | 150 | 70 | 55 | 130 | 1 | 1 | 7 | 610 | 3050 | 4.3 |

| GE110ES GE110ES2RS | 110 | 160 | 70 | 55 | 140 | 1 | 1 | 6 | 655 | 3250 | 4.7 |

| GE120ES GE120ES2RS | 120 | 180 | 85 | 70 | 160 | 1 | 1 | 6 | 950 | 4750 | 8 |

| GE140ES GE140ES2RS | 140 | 210 | 90 | 70 | 180 | 1 | 1 | 7 | 1080 | 5400 | 11 |

| GE160ES GE160ES2RS | 160 | 230 | 105 | 80 | 200 | 1 | 1 | 8 | 1360 | 6800 | 14 |

| GE180ES GE180ES2RS | 180 | 260 | 105 | 80 | 225 | 1 | 1 | 6 | 1530 | 7650 | 18.5 |

| GE200ES GE200ES2RS | 200 | 290 | 130 | 100 | 250 | 1.1 | 1.1 | 7 | 2120 | 10600 | 28 |

| GE220ES GE220ES2RS | 220 | 320 | 135 | 100 | 275 | 1.1 | 1.1 | 8 | 2320 | 11600 | 35.51 |

| GE240ES GE240ES2RS | 240 | 340 | 140 | 100 | 300 | 1.1 | 1.1 | 8 | 2550 | 12700 | 39.91 |

| GE260ES GE260ES2RS | 260 | 370 | 150 | 110 | 325 | 1.1 | 1.1 | 7 | 3030 | 15190 | 51.54 |

| GE280ES GE280ES2RS | 280 | 400 | 155 | 120 | 350 | 1.1 | 1.1 | 6 | 3570 | 17850 | 65.06 |

| GE300ES GE300ES2RS | 300 | 430 | 165 | 120 | 375 | 1.1 | 1.1 | 7 | 3800 | 19100 | 78.07 |

Customizable Lubrication: With maintenance-type bearings, you have control over the lubrication process. This allows you to select the appropriate lubricant based on the specific requirements of your application, such as load, speed, and temperature. Customizable lubrication ensures optimal performance and extends the bearing’s service life.

Enhanced Performance: Regular maintenance and lubrication help to maintain the bearing’s performance at its peak. Adequate lubrication reduces friction, minimizes wear, and prevents premature failure. This results in smooth operation, reduced energy consumption, and extended bearing life, ensuring reliable performance in demanding applications.

Flexibility in Maintenance Intervals: Maintenance-type bearings provide flexibility in scheduling maintenance intervals. You can establish a maintenance plan that aligns with your operational needs and resources. Regular maintenance allows for timely inspection, re-lubrication, and detection of potential issues, minimizing the risk of unexpected failures and maximizing equipment uptime.

Cost-Effective Solution: While maintenance-type bearings require periodic maintenance, they can offer cost-effective solutions in applications where regular maintenance can be performed efficiently. Proper maintenance ensures optimal performance, preventing costly downtime, repairs, and component replacements. By addressing issues proactively, you can extend the bearing’s service life and reduce overall maintenance costs.

Versatility in Applications: Maintenance-type radial spherical plain bearings are versatile components suitable for a wide range of applications. They can handle heavy radial and axial loads and are used in industries such as automotive, agriculture, construction, and industrial machinery. Their versatility makes them compatible with various operating conditions and ensures reliable performance in diverse environments.

Availability of Maintenance Resources: Maintenance-type bearings are widely used, and resources for maintenance, such as lubricants, tools, and expertise, are readily available. This accessibility makes it easier to carry out the required maintenance tasks, ensuring the bearings’ longevity and optimizing their performance.

Wanting more information about TURB? Contact us now! Tell us your need and we will contact with you within 24 hours.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.