Spherical plain thrust bearings, also known as thrust spherical plain bearings, are specialized bearings designed to handle axial loads in a thrust direction. They consist of a spherical inner ring and a convex spherical outer ring with sliding surfaces. These bearings are primarily used in applications where there is a need for axial movement and high load-carrying capacity, such as in heavy-duty machinery, construction equipment, and automotive applications. Spherical plain thrust bearings offer excellent performance, durability, and resistance to misalignment, making them suitable for demanding thrust load applications.

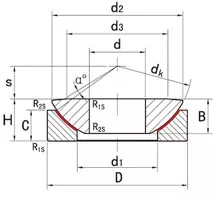

| Part No. | Dimensions mm | Load ratings KN | weight kg | |||||||||||||

| d | D | H | dk | d1 | d2 | d3 | B | C | S | R1s | R2s | a | dyn. | stat. | ||

| min | min | C | C0 | |||||||||||||

| GE10AW | 10 | 30 | 9.5 | 32 | 16.5 | 27.5 | 21 | 7.9 | 6 | 7 | 0.6 | 0.2 | 10 | 36 | 72 | 0.04 |

| GE12AW | 12 | 35 | 13 | 37 | 19.5 | 32 | 24 | 9.3 | 9 | 8 | 0.6 | 0.2 | 9 | 49 | 98 | 0.07 |

| GE15AW | 15 | 42 | 15 | 45 | 24 | 38.9 | 29 | 10.7 | 11 | 10 | 0.6 | 0.2 | 7 | 78 | 156 | 0.12 |

| GE17AW | 17 | 47 | 16 | 50 | 28 | 43.4 | 34 | 11.5 | 11.5 | 11 | 0.6 | 0.2 | 6 | 88 | 176 | 0.16 |

| GE20AW | 20 | 55 | 20 | 60 | 33.5 | 50 | 40 | 14.3 | 13 | 12.5 | 1 | 0.3 | 6 | 112 | 224 | 0.25 |

| GE25AW | 25 | 62 | 22.5 | 66 | 34.5 | 57.5 | 45 | 16 | 17 | 14 | 1 | 0.3 | 7 | 193 | 390 | 0.38 |

| GE30AW | 30 | 75 | 26 | 80 | 44 | 69 | 56 | 18 | 19.5 | 17.5 | 1 | 0.3 | 6 | 255 | 510 | 0.65 |

| GE35AW | 35 | 90 | 28 | 98 | 52 | 84 | 66 | 22 | 20 | 22 | 1 | 0.3 | 6 | 390 | 780 | 1 |

| GE40AW | 40 | 105 | 32 | 114 | 59 | 98 | 78 | 27 | 22 | 24.5 | 1 | 0.3 | 6 | 560 | 1120 | 1.6 |

| GE45AW | 45 | 120 | 36.5 | 130 | 68 | 112 | 89 | 31 | 25 | 27.5 | 1 | 0.3 | 6 | 735 | 1460 | 2.4 |

| GE50AW | 50 | 130 | 42.5 | 140 | 69 | 122.5 | 98 | 33.5 | 32 | 30 | 1 | 0.3 | 5 | 980 | 1960 | 3.3 |

| GE60AW | 60 | 150 | 45 | 160 | 86 | 140 | 108 | 37 | 33 | 35 | 1 | 0.3 | 7 | 1100 | 2200 | 4.5 |

| GE70AW | 70 | 160 | 50 | 170 | 95 | 149.5 | 121 | 40 | 36 | 35 | 1 | 0.3 | 6 | 1200 | 2400 | 5.5 |

| GE80AW | 80 | 180 | 50 | 194 | 108 | 168 | 130 | 42 | 36 | 42.5 | 1 | 0.3 | 6 | 1560 | 3100 | 7 |

| GE100AW | 100 | 210 | 59 | 220 | 133 | 195.5 | 155 | 50 | 42 | 45 | 1 | 0.3 | 7 | 1800 | 3600 | 10.5 |

| GE120AW | 120 | 230 | 64 | 245 | 154 | 214 | 170 | 52 | 45 | 52.5 | 1 | 0.3 | 8 | 1860 | 3750 | 13 |

| GE140AW | 140 | 260 | 72 | 272 | 176 | 244 | 198 | 61 | 50 | 52.5 | 1.5 | 0.6 | 6 | 2450 | 4900 | 18 |

| GE160AW | 160 | 290 | 77 | 310 | 199 | 272 | 213 | 65 | 52 | 65 | 1.5 | 0.6 | 7 | 2850 | 5700 | 23 |

| GE180AW | 180 | 320 | 86 | 335 | 224 | 300 | 240 | 70 | 60 | 67.5 | 1.5 | 0.6 | 8 | 3200 | 6400 | 31 |

| GE200AW | 200 | 340 | 87 | 358 | 246 | 321 | 265 | 74 | 60 | 70 | 1.5 | 0.6 | 8 | 3550 | 7100 | 34 |

| GE220AW | 220 | 370 | 97 | 388 | 265 | 350 | 289 | 82 | 67 | 75 | 1.5 | 0.6 | 7 | 4400 | 8800 | 44.5 |

| GE240AW | 240 | 400 | 103 | 420 | 294 | 382 | 314 | 87 | 73 | 77.5 | 1.5 | 0.6 | 6 | 5200 | 10400 | 55 |

| GE260AW | 260 | 430 | 115 | 449 | 317 | 409 | 336 | 95 | 80 | 82.5 | 1.5 | 0.6 | 7 | 5400 | 10800 | 69 |

| GE280AW | 280 | 460 | 110 | 480 | 337 | 445 | 366 | 100 | 85 | 80 | 3 | 1 | 4 | 8500 | 17000 | 82 |

| GE300AW | 300 | 480 | 110 | 490 | 356 | 460 | 388 | 100 | 90 | 80 | 3 | 1 | 3.5 | 8650 | 17300 | 87 |

| GE320AW | 320 | 520 | 116 | 540 | 380 | 500 | 405 | 105 | 91 | 95 | 4 | 1.1 | 4 | 10600 | 21200 | 109 |

| GE340AW | 340 | 540 | 116 | 550 | 380 | 510 | 432 | 105 | 91 | 95 | 4 | 1.1 | 4 | 11800 | 23600 | 114 |

| GE360AW | 360 | 560 | 125 | 575 | 400 | 535 | 452 | 115 | 95 | 95 | 4 | 1.1 | 4 | 12700 | 25500 | 129 |

Self-Alignment: Spherical plain bearings are designed to accommodate misalignment between the shaft and the housing. The spherical shape of the inner and outer rings allows for angular misalignment, ensuring smooth and reliable operation even in applications with shaft deflection or misalignment. This self-aligning capability helps to reduce stress and prolong the bearing’s service life.

High Load-Carrying Capacity: Spherical plain bearings are engineered to handle high radial and axial loads. The design of the spherical sliding surfaces distributes the load evenly across the bearing, allowing it to bear heavy loads without premature wear or failure. This high load-carrying capacity makes them suitable for applications involving heavy machinery, construction equipment, and automotive components.

Low Friction and Wear: Spherical plain bearings are designed to provide low friction and minimal wear during operation. The sliding surfaces are typically treated with a special coating or made from materials with self-lubricating properties, reducing friction and enhancing the bearing’s efficiency. This results in smoother operation, reduced energy consumption, and extended bearing life.

Broad Temperature Range: Spherical plain bearings can operate effectively across a wide temperature range. They are designed to withstand both high and low temperatures, making them suitable for applications in extreme environments. This temperature resistance ensures the bearings’ reliability and performance in various industrial and automotive applications.

Corrosion Resistance: Many spherical plain bearings are available with corrosion-resistant coatings or made from materials that offer excellent resistance to corrosion. This feature is particularly advantageous in applications exposed to moisture, chemicals, or corrosive environments. The corrosion resistance extends the bearing’s lifespan and maintains its performance under adverse conditions.

Easy Installation and Maintenance: Spherical plain bearings are relatively easy to install and maintain. They can be mounted in various orientations and are often designed with a maintenance-free or low-maintenance concept. This reduces the need for frequent lubrication or maintenance, saving time and effort in the long run.

Wanting more information about TURB? Contact us now! Tell us your need and we will contact with you within 24 hours.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.