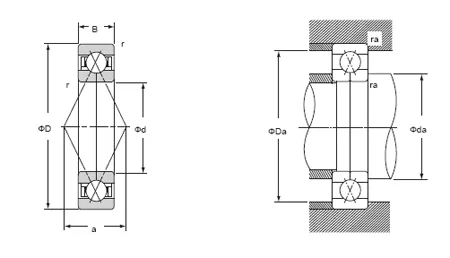

Four-point contact ball bearings are specialized bearings designed to withstand both radial and axial loads in a compact and efficient manner. They feature a unique design with four points of contact between the balls and the raceways, allowing for high load-carrying capacity and improved axial rigidity. These bearings are commonly used in applications such as robotics, machine tools, turntables, and slewing rings, where precise and smooth rotation under heavy loads is required. The four-point contact design ensures optimal load distribution, reduced friction, and enhanced operational stability, making them a reliable choice for demanding applications.

| Bearing Designations | Boundary Dimensions | Basic Load Rating | Limited Speed | distance of | Shoulder Dimension | Mass | |||||||

| working points | |||||||||||||

| d | D | B | r | Cr | Cor | Grease | Oil | a | da | Da | ra | Approx | |

| (min.) | (min.) | (max.) | (max.) | ||||||||||

| 6204BI | 20 | 47 | 14 | 1 | 23.5 | 15.3 | 12000 | 16000 | 23.5 | 25.5 | 41.5 | 1 | 0.129 |

| 6205BI | 25 | 52 | 15 | 1 | 26.7 | 18.8 | 10000 | 14000 | 270 | 30.5 | 46.5 | 1 | 0.156 |

| 6206BI | 30 | 62 | 16 | 1 | 36.3 | 27.6 | 8600 | 12000 | 32.6 | 35.5 | 56.5 | 1 | 0.241 |

| 6207BI | 35 | 72 | 17 | 1.1 | 47.1 | 36.7 | 7500 | 10000 | 37.5 | 42 | 65 | 1 | 0.351 |

| 6208BI | 40 | 80 | 18 | 1.1 | 55.9 | 46.5 | 6600 | 9000 | 42.7 | 47 | 73 | 1 | 0.451 |

| 6209BI | 45 | 85 | 19 | 1.1 | 58.7 | 51.3 | 6100 | 8400 | 45.9 | 52 | 78 | 1 | 0.512 |

| 6210BI | 50 | 90 | 20 | 1.1 | 65.4 | 58 | 5700 | 7900 | 49 | 57 | 83 | 1 | 0.575 |

| 6211BI | 55 | 100 | 21 | 1.5 | 80 | 72.3 | 5200 | 7100 | 54.3 | 63.5 | 91.5 | 1.5 | 0.763 |

| 6212BI | 60 | 110 | 22 | 1.5 | 91.7 | 87.6 | 4600 | 6300 | 60.6 | 68.5 | 101.5 | 1.5 | 0.983 |

| 6213BI | 65 | 120 | 23 | 1.5 | 95.1 | 90.1 | 4300 | 5900 | 64.8 | 73.5 | 111.5 | 1.5 | 1.23 |

| 6214BI | 70 | 125 | 24 | 1.5 | 103 | 99 | 4100 | 5600 | 68.3 | 78.5 | 116.5 | 1.5 | 1.35 |

| 6215BI | 75 | 130 | 25 | 1.5 | 108 | 108 | 3900 | 5300 | 71.8 | 83.5 | 121.5 | 1.5 | 1.47 |

| 6216BI | 80 | 140 | 26 | 2 | 126 | 128 | 3600 | 4900 | 77 | 90 | 130 | 2 | 1.8 |

| 6217BI | 85 | 150 | 28 | 2 | 146 | 150 | 3400 | 4600 | 82.3 | 95 | 140 | 2 | 2.25 |

| 6218BI | 90 | 160 | 30 | 2 | 167 | 173 | 3100 | 4300 | 87.5 | 100 | 150 | 2 | 2.77 |

| 6219BI | 95 | 170 | 32 | 2.1 | 190 | 198 | 3000 | 4100 | 92.8 | 107 | 158 | 2 | 3.37 |

| 6220BI | 100 | 180 | 34 | 2.1 | 201 | 213 | 2800 | 3800 | 98 | 112 | 168 | 2 | 4.02 |

| 6222BI | 110 | 200 | 38 | 2.1 | 242 | 275 | 2500 | 3400 | 108.5 | 122 | 188 | 2 | 5.64 |

| 6304BI | 20 | 52 | 15 | 1.1 | 27.4 | 18.1 | 11000 | 15000 | 25.2 | 27 | 45 | 1 | 0.179 |

| 6305BI | 25 | 62 | 17 | 1.1 | 40.8 | 28 | 9200 | 13000 | 30.5 | 32 | 55 | 1 | 0.285 |

| 6306BI | 30 | 72 | 19 | 1.1 | 49.5 | 36.6 | 7800 | 11000 | 35.7 | 37 | 65 | 1 | 0.426 |

| 6307BI | 35 | 80 | 21 | 1.5 | 61.2 | 46.4 | 7000 | 9600 | 40.3 | 43.5 | 71.5 | 1.5 | 0.565 |

| 6308BI | 40 | 90 | 23 | 1.5 | 74.1 | 57.6 | 6200 | 8500 | 45.5 | 48.5 | 81.5 | 1.5 | 0.778 |

| 6309BI | 45 | 100 | 25 | 1.5 | 87.9 | 70 | 5500 | 7600 | 50.8 | 53.5 | 91.5 | 1.5 | 1.04 |

| 6310BI | 50 | 110 | 27 | 2 | 103 | 83.7 | 5000 | 6900 | 56 | 60 | 100 | 2 | 1.35 |

| 6311BI | 55 | 120 | 29 | 2 | 119 | 98.5 | 4500 | 6200 | 61.3 | 65 | 110 | 2 | 1.72 |

| 6312BI | 60 | 130 | 31 | 2.1 | 145 | 126 | 4100 | 5700 | 67.2 | 72 | 118 | 2 | 2.17 |

| 6313BI | 65 | 140 | 33 | 2.1 | 164 | 145 | 3800 | 5300 | 72.1 | 77 | 128 | 2 | 2.36 |

| 6314BI | 70 | 150 | 35 | 2.1 | 184 | 165 | 3600 | 4900 | 77 | 82 | 138 | 2 | 3.25 |

| 6315BI | 75 | 160 | 37 | 2.1 | 200 | 187 | 3400 | 4600 | 82.3 | 87 | 148 | 2 | 3.9 |

| 6316BI | 80 | 170 | 39 | 2.1 | 217 | 210 | 3100 | 4300 | 87.5 | 92 | 158 | 2 | 4.63 |

| 6317BI | 85 | 180 | 41 | 3 | 234 | 234 | 3000 | 4100 | 92.8 | 99 | 166 | 2.5 | 5.45 |

| 6318BI | 90 | 190 | 43 | 3 | 252 | 260 | 2800 | 3800 | 98 | 104 | 176 | 2.5 | 6.36 |

| 6319BI | 95 | 200 | 45 | 3 | 269 | 287 | 2600 | 3600 | 103.3 | 109 | 186 | 2.5 | 7.37 |

High Load-Carrying Capacity: Four-point contact ball bearings are specifically designed to handle both radial and axial loads simultaneously. The unique design with four points of contact allows for efficient load distribution, enabling these bearings to carry heavy loads with ease. This makes them ideal for applications that require high load capacity, such as in robotics, machine tools, and turntables.

Improved Axial Rigidity: The four-point contact design of these bearings provides enhanced axial rigidity compared to other bearing types. This means that they can withstand axial forces without excessive deformation or loss of performance. The improved axial rigidity ensures stable and precise rotation, making them suitable for applications that demand high precision and minimal deflection, such as slewing rings.

Compact Design: Four-point contact ball bearings have a relatively compact design compared to other types of bearings with similar load-carrying capacity. The four-point contact arrangement allows for a smaller overall bearing size, which is advantageous in applications with limited space or weight constraints. The compact design also contributes to reduced friction and energy consumption.

Smooth and Precise Rotation: The four-point contact design ensures smooth and precise rotation of the bearing. The multiple contact points distribute the load evenly, minimizing the risk of uneven wear and reducing friction. This results in smoother operation, lower noise levels, and improved overall performance.

Versatility in Applications: Four-point contact ball bearings find applications in a wide range of industries and machinery. They are commonly used in robotics, machine tools, turntables, and slewing rings, but can also be found in construction equipment, cranes, and other heavy-duty applications. Their ability to handle both radial and axial loads, along with their compact design and precise rotation, makes them versatile components for various engineering applications.

Long Service Life: Four-point contact ball bearings are designed to provide long service life and reliable performance. The optimized load distribution and reduced friction result in lower wear and extended bearing life. This contributes to reduced maintenance requirements and increased uptime in critical applications.

Wanting more information about TURB? Contact us now! Tell us your need and we will contact with you within 24 hours.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.