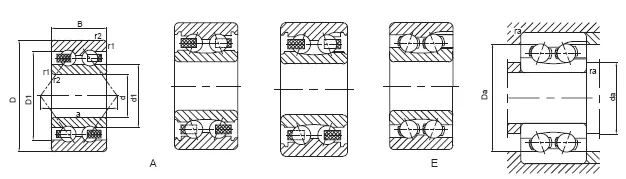

Double row angular contact ball bearings, open type, are precision components designed to accommodate high radial and axial loads in a wide range of applications. With two rows of balls arranged at an angle to the bearing axis, these bearings provide increased load-carrying capacity and improved stiffness compared to single row angular contact ball bearings. The open design allows for easy lubrication and maintenance. They are commonly used in industries such as machine tools, mining equipment, and construction machinery, where reliability, load capacity, and rotational precision are crucial.

| Bearing Designation | Boundary Dimensions | Basic Load Rating (K N ) | Limiting Speed(rpm) | Other dimension | Distance of working points | Shoulder Dimensions (mm) | Mass | ||||||||

| (mm) | Open type | Grease | Oil | (mm) | (kg) | ||||||||||

| OPEN | d | D | B | r1、2min | Cr | Cor | d1≈ | D1≈ | a | da(Min.) | Da(MAX.) | ra(MAX.) | Approx | ||

| 3200A | 10 | 30 | 14 | 0.6 | 7.41 | 4.3 | 16000 | 22000 | 17.7 | 23.6 | 18 | 15 | 25 | 0.6 | 0.051 |

| 3201A | 12 | 32 | 15.9 | 0.6 | 10.1 | 5.6 | 15000 | 20000 | 19.1 | 26.5 | 20 | 17 | 27 | 0.6 | 0.058 |

| 3202A | 15 | 35 | 15.9 | 0.6 | 11.2 | 6.8 | 12000 | 17000 | 22.1 | 29.5 | 22 | 20 | 30 | 0.6 | 0.066 |

| 3203A | 17 | 40 | 17.5 | 0.6 | 14 | 8.65 | 10000 | 15000 | 25.2 | 33.6 | 25 | 22 | 35 | 0.6 | 0.096 |

| 3204A | 20 | 47 | 20.6 | 1 | 18.6 | 12 | 9000 | 13000 | 29.6 | 39.5 | 30 | 26 | 41 | 1 | 0.16 |

| 3205A | 25 | 52 | 20.6 | 1 | 20.3 | 14 | 8000 | 11000 | 34.6 | 44.5 | 33 | 31 | 46 | 1 | 0.18 |

| 3206A | 30 | 62 | 23.8 | 1 | 28.1 | 20 | 7000 | 9500 | 41.4 | 53.2 | 38 | 36 | 56 | 1 | 0.29 |

| 3207A | 35 | 72 | 27 | 1.1 | 37.1 | 27.5 | 6000 | 8000 | 48.1 | 61.9 | 45 | 42 | 65 | 1 | 0.44 |

| 3208A | 40 | 80 | 30.2 | 1.1 | 44.9 | 33.5 | 5600 | 7500 | 47.8 | 72.1 | 49 | 47 | 73 | 1 | 0.58 |

| 3208E | 40 | 80 | 30.2 | 1.1 | 48.4 | 48 | 5600 | 7500 | 47.8 | 72.1 | 49 | 47 | 73 | 1 | 0.64 |

| 3209A | 45 | 85 | 30.2 | 1.1 | 47.5 | 38 | 5000 | 6700 | 52.8 | 77.1 | 52 | 52 | 78 | 1 | 0.63 |

| 3209E | 45 | 85 | 30.2 | 1.1 | 50.1 | 53 | 5000 | 6700 | 52.8 | 77.1 | 52 | 52 | 78 | 1 | 0.69 |

| 3210A | 50 | 90 | 30.2 | 1.1 | 47.5 | 39 | 4800 | 6300 | 57.8 | 82.1 | 56 | 57 | 83 | 1 | 0.66 |

| 3210E | 50 | 90 | 30.2 | 1.1 | 52.8 | 58.5 | 4800 | 6300 | 57.8 | 82.1 | 56 | 57 | 83 | 1 | 0.74 |

| 3211 | 55 | 100 | 33.3 | 1.5 | 57.2 | 67 | 4300 | 5600 | 70.4 | 88.3 | 64 | 64 | 91 | 1.5 | 1.05 |

| 3212 | 60 | 110 | 36.5 | 1.5 | 72.1 | 85 | 3800 | 5000 | 78 | 98.3 | 71 | 69 | 101 | 1.5 | 1.4 |

| 3213 | 65 | 120 | 38.1 | 1.5 | 78.1 | 95 | 3600 | 4800 | 83.7 | 105 | 76 | 74 | 111 | 1.5 | 1.75 |

| 3214 | 70 | 125 | 39.7 | 1.5 | 76.5 | 98 | 3200 | 4300 | 90.6 | 111 | 81 | 79 | 116 | 1.5 | 1.9 |

| 3215 | 75 | 130 | 41.3 | 1.5 | 84.2 | 110 | 3200 | 4300 | 94.7 | 116 | 84 | 84 | 121 | 1.5 | 2.1 |

| 3216 | 80 | 140 | 44.4 | 2 | 101 | 134 | 2800 | 3800 | 102 | 127 | 91 | 90 | 130 | 2 | 2.65 |

| 3217 | 85 | 150 | 49.2 | 2 | 110 | 146 | 2600 | 3600 | 107 | 133 | 97 | 95 | 140 | 2 | 3.4 |

| 3218 | 90 | 160 | 52.4 | 2 | 128 | 173 | 2400 | 3400 | 115 | 143 | 104 | 100 | 150 | 2 | 4.15 |

| 3219 | 95 | 170 | 55.6 | 2.1 | 147 | 204 | 2200 | 3200 | 124 | 154 | 111 | 107 | 158 | 2 | 5 |

| 3220 | 100 | 180 | 60.3 | 2.1 | 157 | 220 | 2000 | 3000 | 129 | 160 | 118 | 112 | 168 | 2 | 6.1 |

| 3222 | 110 | 200 | 69.8 | 2.1 | 190 | 270 | 1900 | 2800 | 143 | 178 | 132 | 122 | 188 | 2 | 8.8 |

| 3302A | 15 | 42 | 19 | 1 | 15.1 | 9.15 | 10000 | 15000 | 25.6 | 34.3 | 26 | 21 | 36 | 1 | 0.13 |

| 3303A | 17 | 47 | 22.2 | 1 | 21.2 | 12.5 | 9500 | 14000 | 27.6 | 38.8 | 29 | 23 | 41 | 1 | 0.18 |

| 3304A | 20 | 52 | 22.2 | 1.1 | 22.1 | 14.3 | 8500 | 12000 | 31.8 | 42.6 | 32 | 27 | 45 | 1 | 0.22 |

| 3305A | 25 | 62 | 25.4 | 1.1 | 31.2 | 20.8 | 7500 | 10000 | 38.4 | 51.4 | 38 | 32 | 55 | 1 | 0.35 |

| 3306A | 30 | 72 | 30.2 | 1.1 | 41 | 28.5 | 6300 | 8500 | 39.8 | 64.1 | 44 | 37 | 65 | 1 | 0.53 |

| 3306E | 30 | 72 | 30.2 | 1.1 | 45.7 | 42.5 | 6300 | 8500 | 39.8 | 64.1 | 44 | 37 | 65 | 1 | 0.59 |

| 3307A | 35 | 80 | 34.9 | 1.5 | 48.8 | 34 | 5600 | 7500 | 44.6 | 70.1 | 49 | 44 | 71 | 1.5 | 0.73 |

| 3307E | 35 | 80 | 34.9 | 1.5 | 53.9 | 51 | 5600 | 7500 | 44.6 | 70.1 | 49 | 44 | 71 | 1.5 | 0.79 |

| 3308A | 40 | 90 | 36.5 | 1.5 | 59.2 | 43 | 5000 | 6700 | 50.8 | 80.1 | 56 | 49 | 81 | 1.5 | 0.95 |

| 3308E | 40 | 90 | 36.5 | 1.5 | 66 | 64 | 5000 | 6700 | 50.8 | 80.1 | 56 | 49 | 81 | 1.5 | 1.05 |

| 3309 | 45 | 100 | 39.7 | 1.5 | 72.1 | 73.5 | 4500 | 6000 | 63.8 | 86.3 | 64 | 54 | 91 | 1.5 | 1.4 |

| 3310 | 50 | 110 | 44.4 | 2 | 88 | 96.5 | 4000 | 5300 | 73.3 | 97 | 73 | 60 | 100 | 2 | 1.95 |

| 3311 | 55 | 120 | 49.2 | 2 | 95.2 | 108 | 3800 | 5000 | 81 | 110 | 80 | 65 | 110 | 2 | 2.55 |

| 3312 | 60 | 130 | 54 | 2.1 | 112 | 127 | 3400 | 4500 | 87.2 | 115 | 86 | 72 | 118 | 2 | 3.25 |

| 3313 | 65 | 140 | 58.7 | 2.1 | 128 | 150 | 3200 | 4300 | 92.5 | 122 | 94 | 77 | 128 | 2 | 4.1 |

| 3314 | 70 | 150 | 63.5 | 2.1 | 147 | 173 | 2800 | 3800 | 99.2 | 131 | 101 | 82 | 138 | 2 | 5.05 |

| 3315 | 75 | 160 | 68.3 | 2.1 | 157 | 186 | 2600 | 3600 | 106 | 139 | 107 | 87 | 148 | 2 | 6.15 |

| 3316 | 80 | 170 | 68.3 | 2.1 | 176 | 212 | 2400 | 3400 | 113 | 148 | 112 | 92 | 158 | 2 | 6.95 |

| 3317 | 85 | 180 | 73 | 3 | 194 | 240 | 2200 | 3200 | 120 | 157 | 119 | 99 | 166 | 2.5 | 8.3 |

| 3318 | 90 | 190 | 73 | 3 | 220 | 285 | 2000 | 3000 | 128 | 169 | 125 | 104 | 176 | 2.5 | 9.25 |

| 3319 | 95 | 200 | 77.8 | 3 | 238 | 315 | 1900 | 2800 | 135 | 178 | 133 | 109 | 186 | 2.5 | 11 |

| 3320 | 100 | 215 | 82.6 | 3 | 255 | 355 | 1800 | 2600 | 142 | 187 | 139 | 114 | 201 | 2.5 | 13.5 |

| 3322 | 110 | 240 | 92.1 | 3 | 292 | 425 | 1700 | 2400 | 155 | 205 | 153 | 124 | 226 | 2.5 | 19 |

Increased Load-Carrying Capacity: Double row angular contact ball bearings have two rows of balls arranged at an angle, providing higher load-carrying capacity compared to single row bearings. This design enables them to handle both radial and axial loads effectively, making them suitable for applications with heavy loads or combined loads.

Improved Stiffness: The double row configuration of these bearings enhances their stiffness, resulting in improved stability and reduced deflection during operation. This increased rigidity allows for precise and accurate rotational motion, ensuring the desired performance and minimizing any unintended movement.

Versatility in Applications: Double row angular contact ball bearings find applications in various industries, including machine tools, mining equipment, construction machinery, and more. Their ability to handle high loads and provide improved stiffness makes them suitable for demanding applications that require reliable and precise motion control.

Open Design for Easy Lubrication and Maintenance: The open type design of these bearings allows for easy access to lubrication points, facilitating regular maintenance and ensuring proper lubrication to prolong the bearing’s lifespan. This feature also enables easy inspection and cleaning of the bearing assembly.

Higher Speed Capability: Double row angular contact ball bearings are engineered to withstand higher rotational speeds while maintaining stable and reliable operation. Their design minimizes friction and heat generation, allowing for efficient and smooth operation even at elevated speeds.

Durability and Longevity: These bearings are manufactured with high-quality materials and undergo rigorous testing to ensure durability and long-lasting performance. They are designed to withstand challenging operating conditions, including heavy loads, high speeds, and harsh environments, ensuring reliable performance over an extended period.

Wanting more information about TURB? Contact us now! Tell us your need and we will contact with you within 24 hours.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.