Miniature Ball Bearings are compact and small-sized bearings that are commonly used in applications requiring precise rotation and low friction. These bearings, typically with an outer diameter of less than 30 mm, offer excellent performance in limited-space environments. With their miniature size and high rotational speed capabilities, they find extensive use in industries such as robotics, electronics, medical devices, and precision instruments. Miniature Ball Bearings provide smooth and reliable operation, reducing energy consumption and extending the lifespan of equipment. Their small form factor and precision make them ideal for applications where space and accuracy are critical.

| Bearing Designation | Boundary Dimensions | Basic Load Rating | Limiting Speed | Shoulder Dimensions | Mass | ||||||||||||||

| (mm) | (kN) | (rpm) | (mm) | (g) | |||||||||||||||

| Grease | Oil | ||||||||||||||||||

| Open type | With steel shields | Without | With contacting | d | D | B | B1 | r | r1 | Cr | Cor | Open Type | (2RS) | Open Type | da | Da | ra | rb | Approx |

| contacting | rubber seals | (min.) | (min.) | (ZZ,2RU) | (Z) | (min.) | (max.) | (max.) | (max.) | ||||||||||

| rubber seals | |||||||||||||||||||

| 604 | 604 ZZ | 604 2RU | 604 2RS | 4 | 12 | 4 | 4 | 0.2 | 0.2 | 0.97 | 0.36 | 53000 | 0 | 63000 | 5.6 | 10.4 | 0.2 | 0.2 | 2.1 |

| 605 | 605 ZZ | 605 2RU | 605 2RS | 5 | 14 | 5 | 5 | 0.2 | 0.2 | 1.3 | 0.49 | 50000 | 0 | 60000 | 6.6 | 12.4 | 0.2 | 0.2 | 3.5 |

| 606 | 606 ZZ | 606 2RU | 606 2RS | 6 | 17 | 6 | 6 | 0.3 | 0.3 | 1.95 | 0.74 | 43000 | 0 | 51000 | 8 | 15 | 0.3 | 0.3 | 5.8 |

| 607 | 607 ZZ | 607 2RU | 607 2RS | 7 | 19 | 6 | 6 | 0.3 | 0.3 | 2.6 | 1.05 | 40000 | 27000 | 47000 | 9 | 17 | 0.3 | 0.3 | 7.6 |

| 608 | 608 ZZ | 608 2RU | 608 2RS | 8 | 22 | 7 | 7 | 0.3 | 0.3 | 3.3 | 1.35 | 34000 | 23000 | 41000 | 10 | 20 | 0.3 | 0.3 | 12 |

| 609 | 609 ZZ | 609 2RU | 609 2RS | 9 | 24 | 7 | 7 | 0.3 | 0.3 | 3.35 | 1.4 | 33000 | 22000 | 40000 | 11 | 22 | 0.3 | 0.3 | 15 |

| 623 | 623 ZZ | 623 2RU | 623 2RS | 3 | 10 | 4 | 4 | 0.15 | 0.15 | 0.64 | 0.23 | 52000 | 44000 | 63000 | 4.2 | 8.8 | 0.15 | 0.15 | 1.6 |

| 624 | 624 ZZ | 624 2RU | 624 2RS | 4 | 13 | 5 | 5 | 0.2 | 0.2 | 1.3 | 0.49 | 44000 | 39000 | 54000 | 5.6 | 11.4 | 0.2 | 0.2 | 2.9 |

| 625 | 625 ZZ | 625 2RU | 625 2RS | 5 | 16 | 5 | 5 | 0.3 | 0.3 | 1.75 | 0.67 | 40000 | 33000 | 49000 | 7 | 14 | 0.3 | 0.3 | 5 |

| 626 | 626 ZZ | 626 2RU | 626 2RS | 6 | 19 | 6 | 6 | 0.3 | 0.3 | 2.6 | 1.05 | 35000 | 27000 | 43000 | 8 | 17 | 0.3 | 0.3 | 8.1 |

| 627 | 627 ZZ | 627 2RU | 627 2RS | 7 | 22 | 7 | 7 | 0.3 | 0.3 | 3.3 | 1.35 | 31000 | 23000 | 37000 | 9 | 20 | 0.3 | 0.3 | 13 |

| 628 | 628 ZZ | 628 2RU | 628 2RS | 8 | 24 | 8 | 8 | 0.3 | 0.3 | 3.35 | 1.4 | 28000 | 22000 | 35000 | 10 | 22 | 0.3 | 0.3 | 18 |

| 629 | 629 ZZ | 629 2RU | 629 2RS | 9 | 26 | 8 | 8 | 0.6 | 0.6 | 4.55 | 2 | 27000 | 19000 | 33000 | 13 | 22 | 0.3 | 0.3 | 20 |

| 633 | 633 ZZ | 633 2RU | 633 2RS | 3 | 13 | 5 | 5 | 0.2 | 0.2 | 1.3 | 0.49 | 44000 | 0 | 54000 | 4.6 | 11.4 | 0.2 | 0.2 | 3 |

| 634 | 634 ZZ | 634 2RU | 634 2RS | 4 | 16 | 5 | 5 | 0.3 | 0.3 | 1.75 | 0.67 | 40000 | 0 | 49000 | 6 | 14 | 0.3 | 0.3 | 5.3 |

| 635 | 635 ZZ | 635 2RU | 635 2RS | 5 | 19 | 6 | 6 | 0.3 | 0.3 | 2.6 | 1.05 | 35000 | 27000 | 43000 | 7 | 17 | 0.3 | 0.3 | 8.5 |

| 636 | 636 ZZ | 636 2RU | 636 2RS | 6 | 22 | 7 | 7 | 0.3 | 0.3 | 3.3 | 1.35 | 31000 | 23000 | 37000 | 8 | 20 | 0.3 | 0.3 | 13 |

| 637 | 637 ZZ | 637 2RU | 637 2RS | 7 | 26 | 9 | 9 | 0.3 | 0.3 | 4.55 | 1.95 | 26000 | 0 | 32000 | 9 | 24 | 0.3 | 0.3 | 24 |

| 638 | 638 ZZ | 638 2RU | 638 2RS | 8 | 28 | 9 | 9 | 0.3 | 0.3 | 4.55 | 1.95 | 26000 | 0 | 32000 | 10 | 26 | 0.3 | 0.3 | 29 |

| 639 | 639 ZZ | 639 2RU | 639 2RS | 9 | 30 | 10 | 10 | 0.6 | 0.6 | 6 | 2.65 | 24000 | 0 | 29000 | 13 | 26 | 0.6 | 0.6 | 35 |

| 694 | 694 ZZ | 694 2RU | 694 2RS | 4 | 11 | 4 | 4 | 0.15 | 0.15 | 0.96 | 0.35 | 54000 | 44000 | 65000 | 5.2 | 9.8 | 0.15 | 0.15 | 1.8 |

| 695 | 695 ZZ | 695 2RU | 695 2RS | 5 | 13 | 4 | 4 | 0.2 | 0.2 | 1.3 | 0.49 | 50000 | 42000 | 60000 | 6.6 | 11.4 | 0.2 | 0.2 | 2.2 |

| 696 | 696 ZZ | 696 2RU | 696 2RS | 6 | 15 | 5 | 5 | 0.2 | 0.2 | 1.75 | 0.67 | 45000 | 32000 | 54000 | 7.6 | 13.4 | 0.2 | 0.2 | 3.9 |

| 697 | 697 ZZ | 697 2RU | 697 2RS | 7 | 17 | 5 | 5 | 0.3 | 0.3 | 1.6 | 0.71 | 42000 | 28000 | 50000 | 9 | 15 | 0.3 | 0.3 | 5.3 |

| 698 | 698 ZZ | 698 2RU | 698 2RS | 8 | 19 | 6 | 6 | 0.3 | 0.3 | 2.25 | 0.91 | 39000 | 27000 | 46000 | 10 | 17 | 0.3 | 0.3 | 7.2 |

| 699 | 699 ZZ | 699 2RU | 699 2RS | 9 | 20 | 6 | 6 | 0.3 | 0.3 | 2.45 | 1.05 | 35000 | 25000 | 42000 | 11 | 18 | 0.3 | 0.3 | 7.5 |

| 602 | 602 ZZ | 602 2RU | 602 2RS | 2 | 7 | 2.8 | 3.5 | 0.15 | 0.15 | 0.39 | 0.13 | 76000 | 0 | 79000 | 3.2 | 5.8 | 0.15 | 0.15 | 0.5 |

| 603 | 603 ZZ | 603 2RU | 603 2RS | 3 | 9 | 3 | 5 | 0.15 | 0.15 | 0.43 | 0.16 | 60000 | 0 | 72000 | 4.2 | 7.8 | 0.15 | 0.15 | 0.9 |

| 68/2.5 | 68/2.5 ZZ | 68/2.5 2RU | 68/2.5 2RS | 2.5 | 6 | 1.8 | 2.6 | 0.1 | 0.1 | 0.19 | 0.06 | 75000 | 0 | 89000 | 3.3 | 5.2 | 0.1 | 0.1 | 0.2 |

| 682 | 682 ZZ | 682 2RU | 682 2RS | 2 | 5 | 1.5 | 2.3 | 0.1 | 0.1 | 0.19 | 0.06 | 98000 | 0 | 110000 | 2.8 | 4.4 | 0.1 | 0.1 | 0.1 |

| 683 | 683 ZZ | 683 2RU | 683 2RS | 3 | 7 | 2 | 3 | 0.15 | 0.15 | 0.31 | 0.11 | 66000 | 0 | 79000 | 4.2 | 5.8 | 0.1 | 0.1 | 0.3 |

| 684 | 684 ZZ | 684 2RU | 684 2RS | 4 | 9 | 2.5 | 4 | 0.15 | 0.15 | 0.64 | 0.23 | 59000 | 0 | 70000 | 5.2 | 7.8 | 0.1 | 0.1 | 0.6 |

| 685 | 685 ZZ | 685 2RU | 685 2RS | 5 | 11 | 3 | 5 | 0.15 | 0.15 | 0.97 | 0.36 | 53000 | 0 | 63000 | 6.2 | 9.8 | 0.15 | 0.15 | 0.1 |

| 686 | 686 ZZ | 686 2RU | 686 2RS | 6 | 13 | 3.5 | 5 | 0.15 | 0.15 | 1.1 | 0.44 | 48000 | 36000 | 57000 | 7.2 | 11.8 | 0.15 | 0.15 | 1.8 |

| 687 | 687 ZZ | 687 2RU | 687 2RS | 7 | 14 | 3.5 | 5 | 0.15 | 0.15 | 1.15 | 0.51 | 45000 | 0 | 54000 | 8.2 | 12.8 | 0.15 | 0.15 | 2 |

| 688 | 688 ZZ | 688 2RU | 688 2RS | 8 | 16 | 4 | 5 | 0.2 | 0.2 | 1.6 | 0.71 | 42000 | 28000 | 50000 | 9.6 | 14.4 | 0.2 | 0.2 | 3.2 |

| 689 | 689 ZZ | 689 2RU | 689 2RS | 9 | 17 | 4 | 5 | 0.2 | 0.2 | 1.35 | 0.66 | 39000 | 0 | 46000 | 10.6 | 15.4 | 0.2 | 0.2 | 3.5 |

| 69/2.5 | 69/2.5 ZZ | 69/2.5 2RU | 69/2.5 2RS | 2.5 | 7 | 2.5 | 3.5 | 0.15 | 0.15 | 0.31 | 0.11 | 66000 | 0 | 79000 | 3.7 | 5.8 | 0.15 | 0.15 | 0.4 |

| 692 | 692 ZZ | 692 2RU | 692 2RS | 2 | 6 | 2.3 | 3 | 0.15 | 0.1 | 0.33 | 0.1 | 86000 | 0 | 100000 | 3.2 | 4.8 | 0.15 | 0.1 | 0.2 |

| 693 | 693 ZZ | 693 2RU | 693 2RS | 3 | 8 | 3 | 4 | 0.15 | 0.15 | 0.55 | 0.17 | 64000 | 0 | 76000 | 4.2 | 6.8 | 0.15 | 0.15 | 0.6 |

Space-saving: The compact size of Miniature Ball Bearings allows for efficient use of limited space in various applications. They are particularly useful in devices and equipment where size constraints exist.

Low friction: These bearings are designed to minimize friction and provide smooth rotational motion. This reduces energy consumption and ensures efficient operation, making them suitable for applications where power efficiency is crucial.

High precision: Miniature Ball Bearings are manufactured with high precision, resulting in accurate and reliable performance. They are commonly used in precision instruments, optical devices, and robotics, where precise movements and positioning are required.

High rotational speed: Despite their small size, Miniature Ball Bearings can handle high rotational speeds. This makes them suitable for applications that demand quick and precise motion, such as small motors, machine tools, and high-speed machinery.

Long lifespan: Miniature Ball Bearings are engineered for durability and long service life. They are manufactured using high-quality materials and advanced manufacturing techniques, ensuring their ability to withstand demanding operating conditions.

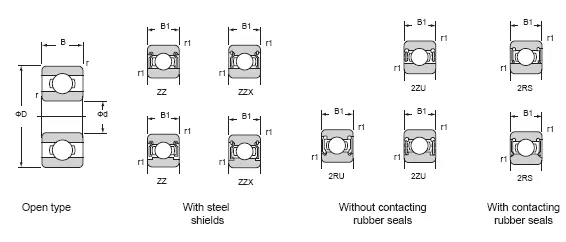

Versatility: Miniature Ball Bearings are available in a wide range of configurations, including open, shielded, and sealed designs. This versatility allows them to be adapted to various environments and operating conditions, making them suitable for diverse applications.

Wanting more information about TURB? Contact us now! Tell us your need and we will contact with you within 24 hours.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.